Mixers and agitators have a heavy load to carry – and they’re typically supported by only two bearings. Apart from the large load, these bearings must also be able to withstand a wide range of temperatures and chemicals.

...Mixers and agitators have a heavy load to carry – and they’re typically supported by only two bearings. Apart from the large load, these bearings must also be able to withstand a wide range of temperatures and chemicals.

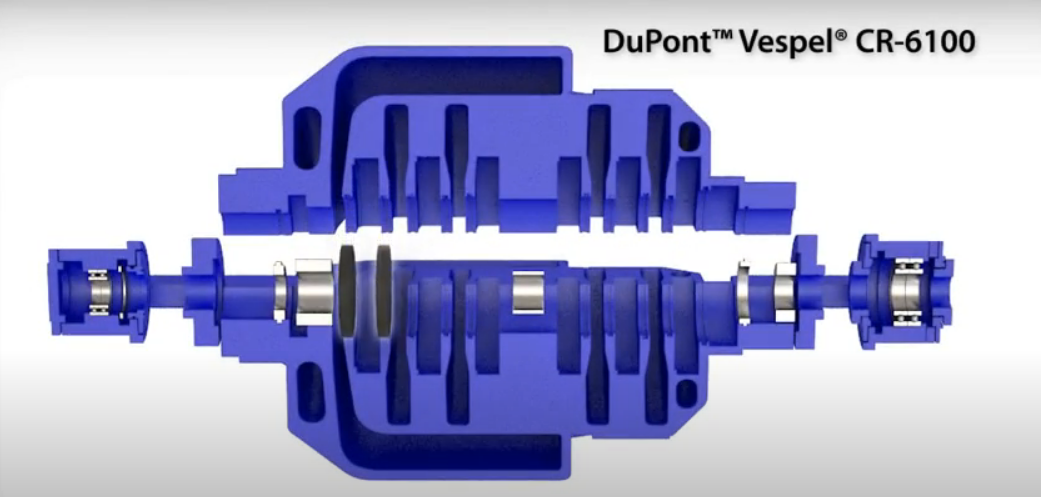

...Hydrogen fluoride, or hydrofluoric acid, is often used in specialized chemical processes. That means hydrofluoric acid pumps need to work efficiently AND be able to withstand the presence of a strong acid.

...Hydrogen fluoride, or hydrofluoric acid, is often used in specialized chemical processes. That means hydrofluoric acid pumps need to work efficiently AND be able to withstand the presence of a strong acid.

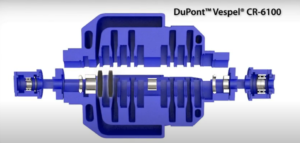

...Switching to Vespel® CR-6100 may seem like a small change, but it can offer big results. After making this change with Boulden Company, a fertilizer plant in Canada eliminated pump seizures, was able to run at full capacity with one pump, could save their second pump for 100% spare capacity and saved over $30,000 in one year, which paid for the upgrade in just months.

...Switching to Vespel® CR-6100 may seem like a small change, but it can offer big results. After making this change with Boulden Company, a fertilizer plant in Canada eliminated pump seizures, was able to run at full capacity with one pump, could save their second pump for 100% spare capacity and saved over $30,000 in one year, which paid for the upgrade in just months.

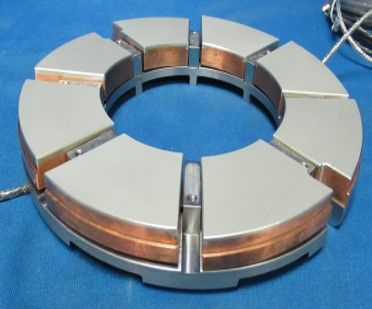

...We have exciting news! As part of our relentless pursuit of innovative solutions, Boulden has acquired Gulf Coast Bearing & Seal. This acquisition adds adjacent products and aftermarket service for turbomachinery to our solutions portfolio, so we can continue to offer long-term solutions that solve problems in the here and now. Welcome to the team, Gulf Coast Bearing & Seal!

...We have exciting news! As part of our relentless pursuit of innovative solutions, Boulden has acquired Gulf Coast Bearing & Seal. This acquisition adds adjacent products and aftermarket service for turbomachinery to our solutions portfolio, so we can continue to offer long-term solutions that solve problems in the here and now. Welcome to the team, Gulf Coast Bearing & Seal!

...Power plant operators face operational challenges that stress their equipment in ways not anticipated at commissioning. Power plants designed and constructed as baseline plants are now balancing the load from intermittent power sources such as solar and wind generation. For many plants, this creates new operational challenges for machinery which was not designed for stop/start operation.

...Power plant operators face operational challenges that stress their equipment in ways not anticipated at commissioning. Power plants designed and constructed as baseline plants are now balancing the load from intermittent power sources such as solar and wind generation. For many plants, this creates new operational challenges for machinery which was not designed for stop/start operation.

...